The 7 Biggest Problems with Paper T&M Tickets

Time & Material Tags (aka tickets, EWAs, FWOs, etc.) are synonymous with headaches in the commercial construction industry. Written by hand out in the field, they are painful to create and track and often more painful to receive.

GCs & Subs:

It's not just you. Everyone hates paper T&M Tickets.

1. Handwritten T&M Tickets are almost always awful to read

This sounds obvious, but how many times have you (or someone on your team) stared at a T&M Ticket, trying to decipher what it even says, let alone whether or not it’s accurate?

Folks in the field are typically documenting legitimate labor, material and equipment used to complete field-directed extra work, but also they’re balancing 1000 other pressing project needs. They’re in a hurry, running around with a clipboard or finding some other makeshift flat surface, just trying to get through documenting that work. Not shockingly, handwritten T&M Tickets regularly turn into a mess of chicken scratch.

The delays start when the office staff has to go back and clarify the information. There’s a domino effect of Change Order processing delays from there. If the Sub tries to push it through as-is, the Tickets are often just flat-out rejected for being illegible once they hit the GC's inbox.

2. Do you know how many steps it actually takes to attach photos to paper T&M Tickets?

Photos are worth a thousand words and make it simple for customers to understand the work your T&M Ticket represents. But how do you attach a photo to a piece of paper?

First, someone is scanning the handwritten Ticket. Someone else is digging through their phone for photos, drafting an email, attaching the photos and explaining what’s in each one. In an ideal world, those photos are being pulled from the email and attached to the original scanned Ticket as part of a Change Order Request, but given the time requirements, how often is that getting skipped? It’s getting skipped often.

If photo documentation isn’t included, it's that much more likely the T&M Ticket is simply getting rejected by the GC. Emails have been wasted, the Subcontractor team is going back trying to re-clarify and the whole process circles back to more emails.

3. Delays in processing time

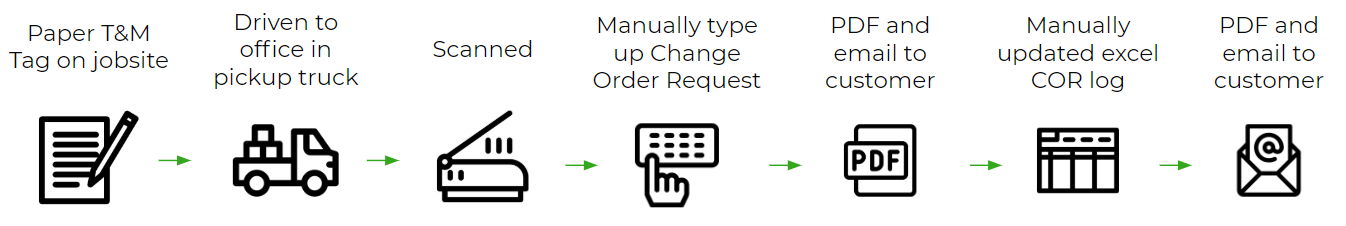

Did you know the average time between a Subcontractor receiving a signed T&M Ticket and processing a Change Order is 24 days? Take a look at the typical process for using paper T&M Tickets:

The bottom line: Extra work tracked on paper ensures inefficiencies and delays in getting T&M Tickets processed. Those delays turn into confusion and forgotten conversations between the GC and Sub and make the “he said/she said” scenario exponentially more likely.

4. T&M Tickets get lost

Subcontractors: Do you know how many paper Tickets are floating around on site, in your foreman’s truck, or elsewhere right now? Chances are, you don’t. Subcontractors estimate that anywhere from 2-5% of T&M Tickets go missing. Missing Tickets don’t get submitted and that can add up to thousands of dollars in legitimate lost revenue.

5. Lack of oversight prior to signatures

Subcontractors: Have you or your foreman ever filled out a T&M Ticket and not been able to get it signed? How do you keep tabs on which Tickets are pending signatures or do you just give up or submit them without signatures?

With paper T&M Tickets, it’s incredibly difficult to create and maintain a paper trail (pun intended) of when the Ticket was created, when it was requested for signature and how many times you had to follow up, etc.

GCs: Do you have a realistic idea of how many T&M Tickets are floating out there on any given project, waiting for signatures across all of your Subs? Or, is it more likely you’re going to get blindsided with a bunch of T&M-based Change Orders that weren’t accounted for in your COR Log because there were scores of Tickets still working their way through the process?

6. Subcontractors wind up financing projects

In the typical 24+ days between getting a T&M Ticket signed and a Change Order Request issued, Subcontractors have spent real money on uncompensated work and are awaiting payment. This puts a financial strain on Subcontractors and presents huge risks if payments are denied or delayed.

7. No transparency between companies

We touched on this earlier. In a perfect world, a General Contractor will log each paper T&M Ticket and forecast the cost they just approved in their project’s financial reporting system. But given the realities of fast-paced, complex construction projects, there is almost never time to do this efficiently.

Instead, the GC project team is relying on the Subcontractor to professionally document their T&M Ticket work, quickly process an associated Change Order Request and present the costs to the General Contractor.

If a General Contractor is tracking two weeks of overtime work, they are likely not going to know the true cost exposure until after the work is completed. This can lead to disputes, frustrations and unwanted financial surprises. Without the ability to see T&M Ticket costs accruing in real-time, the GC has no way to accurately inform clients where they stand financially.

![]()

The Solution

You know where we’re going with this. Using Clearstory's digital Time & Material Tags and a centralized Change Order Communication Tool, you can eliminate these seven challenges of traditional paper processing.

Clearstory is the only Change Order Communication Tool that puts Subcontractors, GCs and Owners all on the same page, sharing Change Order information in real time. Schedule a demo with our team to learn more.